Screw Extractor Friction Drops

Bolt Friction Drops

Friction Enhancer Friction Drops

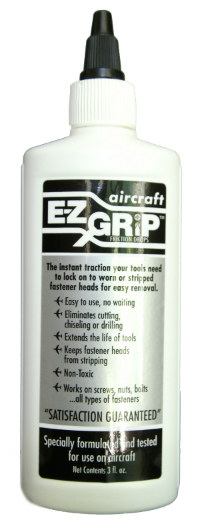

Extracting screws, removing bolts, and adding grip to your tools is made easy and quick with EZ Grip Friction Drops©. Removing screws and removing bolts that are worn, damaged or corroded means EZ Grip Screw Extractor needs to come out of your toolbox and onto the job. Add friction to your driver or wrench for tightening screws and bolts without damaging them or your tool. Pull cable without slipping with this simple biodegradable tool. Save your knuckles and extend tool life with EZ Grip Friction Drops© Screw Extractor.

Each drop of our Aircraft Grade solution has thousands of hardened aluminum cubes in a non-toxic, food-grade antifreeze carrying agent. These building blocks provide a temporary bridge between the tool and stressed fastener heads for easy screw removal and bolt removal. It has no silicone's to hinder sealing/painting operations on metal surfaces. So, no problem with worn screw removal and bolt removal operations while performing aircraft maintenance. Use EZ Grip Friction Drops©. This product has met ASTM Tests for aircraft use as listed on our home page.

AIRCRAFT GRADE

Military Part # E-Z59183

NSN 6850-01-418-8759

3 Fl. oz.

12 per case

Our Commercial grade friction drops are ideal for home or factory use to remove worn screw removal and bolt removal. The Commercial Grade solution has thousands of hardened aluminum cubes in a non-toxic, food grade antifreeze carrying agent. These building blocks provide a temporary bridge between the tool and stressed fastener heads for easy damaged screw removal and bolt removal.

COMMERCIAL

3 Fl. oz.

12 per case

When damaged screw removal or damaged bolt removal is a problem in wet environments, such as aircraft maintenance and equipment maintenance on aircraft carrier flight decks and other ship maintenance, EZ Grip Friction Drops©, Marine Grade give you the torque your tools need for worn fastener removal. For use above or below water, EZ Grip Friction Drops©, Marine Grade is the answer for screw removal or bolt removal.

MARINE GRADE

Military Part # E-Z59172

NSN 6850-01-420-9041

3 Fl. oz.

12 per case

FAQ

Q. How does EZ Grip Screw Extractor and bolt remover work?

A. Each drop of ©EZ Grip Friction Drops™ contain thousands of microscopic blocks of natural material that are almost diamond like in hardness. These natural blocks are floating in a specially blended biodegradable formula. When you place a drop on the fastener head or driver head or onto the bolt or socket or wrench head and jiggle it this is what happens: The blocks quickly move into place to form an interlocking bridge between the tool head and any differential surface it can find on the fastener head. You can feel the tool lock onto the fastener and while you apply pressure, then turn. Unless the fastener is so frozen that it needs a lubricant to free it, it will turn.

Q. Does EZ Grip Screw Extractor get tacky of hard.

A. No, there is no waiting and the friction drops will not adhere to the tool or fastener.

Q. How can this be demonstrated?

A. Do the quarter demo. Take two coins and press them between your thumb and index fingers, press them together hard and try to slide them against each other – -of course they slide. Now take the coins and place a drop of EZ Grip Screw Extractor between them and do the same test. They don’t slide because the microscopic blocks have quickly moved into place around the shallow artwork on the coins and when you pressed them together firmly they temporarily interlocked with each other. They have formed a temporary bridge between differential surfaces on the coins. Relax your pressure on the coins and they will slide, apply the pressure and they will lock and not slide.

Q. Do I have to clean off the EZ Grip screw remover from my driver or part surface I am working on?

A. If you want to, but you don’t have to. When exposed to air for a day or so, the ©EZ Grip Friction Drop’s™ Aircraft Grade and Commercial Grade biodegradable carrying agent will evaporate and what seems like an extremely fine powder will blow away. These are the natural blocks spoken of earlier. NOTE: There is no silicone in this product! You do not need to be concerned about priming and painting operations on aircraft or parts surfaces after use as it will not interfere as silicone will.

The Marine Grade EZ Grip Screw Extractor is made to resist water and wiping it with a cloth or with water only spreads it around more. But an amazing thing happens when you use a little dish detergent in water to wipe it away, it cleans off immediately.

Q. If I don’t clean off the EZ Grip screw removal drops will my tools or parts surface corrode from it.

A. Absolutely not. The carrying agent is specifically formulated to prevent any corrosion to metal surfaces and will not attack O-rings. Click the section on our home page called: ASTM & Military Testing Results

Q. What if the screw or bolt won’t come out.

A. EZ Grip Screw Extractor is designed to interlock your driver or wrench head with the fastener head and increase the torque to help turn the head. If the threads are so frozen in the tap hole that you cannot turn it out try a heavy duty lubricant. I recommend PB Penetrating Catalyst made by P’Blaster. You can buy it at your NAPA dealer. If that won’t break it free after soaking in it nothing will.

Q. Why can’t I just use any small gritty stuff like sand or dust around my bench grinder in some liquid or paste to add torque to my tool head?

A. The particles need to be microscopic, extremely hard, and be in blockish form to work. Round particles will roll and non-hardened particles will bend under the tremendous foot pounds of pressure typically exerted on the fastener by the tool. Our blocks are “extremely hard but not brittle”. Brittle particles will shatter, and if the particles are not the right size they will not form the necessary bridge between the smallest of differential surfaces.

Another thing is the carrying agent in the EZ Grip Screw Extractor product line. The drops consist of a very precisely blended formula of natural ingredients that allow the blocks to move quickly into place, form up with each other and bridge the tool/fastener surfaces, lock under pressure, and release under relief pressure. The liquid must be exactly the correct consistency to do its job but not separate.

Chemical separation will cause the blocks to spread unevenly and form into clumps. Our blending operation is precise and consistent, the ingredients exact and the overall manufacturing process a company secret, time consuming and well worth it. It is truly a miracle in a bottle.

Q. What is the shelf life of EZ Grip Screw Extractor?

A. Shelf life exceeds 12 years but we say 10 to be safe. Frankly, we aren’t sure how long after that because our tests show that if you keep the twist on/ twist off applicator cap closed after use it’s shelf life is indefinite.

Testimonials

Your tank/automotive, aviation and marine mechanics will appreciate E-Z Grip now available in the supply system under MSN 6850-01-420-9041 for wet applications and 6850-01-418-8759 for aviation and tank automotive maintenance applications.

If you are having trouble with stripped or cambered out fasteners (screw, Nut, Bolt, Allen) or your tool is worn out and won't grab (Wrench, Pliers, Socket, Pipe Wrench) or if your tool is misaligned to the fastener, and you know it might slip off and strip a fastener and bust your knuckles, you can now put a drop or more of E-Z Grip friction drops on your tool or fastener and jiggle your tool in the fastener to align particles to increase the gripping power. You can also use it as a preventative so you will not strip the fastener next time you need to remove it. Saves wear on tools and your knuckles too.

We have tried it here at APO and it works very well.

CWS Duncan

Office Chief of Ordnance

APO, MD

Boeing Commercial Al@ Group P.O. Box 3707 Seattle, WA 98124-2207

October 13, 1995

Dear . . .

It was a pleasure having you come to our facilities on Friday October 6, and demonstrating the E/Z Grip compound to us.

When I first received the phone call from Bob Findley, your Seattle associate, I was a little reluctant to have all our other groups involved. I took the chance, based on what Bob said, and the results have been overwhelming.

As of Tuesday, October 10, I received a verbal okay from our Boeing Material Technology Division to use the product on stripped fasteners. This was based on the MSDS and performance. That afternoon, I demonstrated the product to some senior level managers along with other developments. The response has been very positive, with comments such as 11 Should have had this years ago".

On Thursday, October 12, E/Z Grip was shown to the U.S. Army Reserve Center, and British Airways. Both demonstrations were so positive, that one remark was, "The price was insignificant to the cost of the maintenance task".

I have never seen any item ever get approval in Boeing for use in three working days. I have told some colleagues of mine that I have to frame the approval memo. I have though'-. of sending it to Frank Schrontz, our CEO. You definitely have a miracle compound.

Regards,

M. Williamson

BOEING CUSTOMER SERVICES 2925 S. 112TH M/S 2L-08 SEATTLE, WA. 98168

DEPARTMENT OF THE AIR FORCE

HEADQUARTERS WARNER ROBINS AIR LOG ISTR-S CEN7ER (AFWC)

2 Aug 95

TO WHOM IT MAY CONCERN'

Having tried the product E/Z Grip here at Robins AFB, we hereby attest to its effectiveness in removing damaged fasteners.

If this product is made available, the expected benefits would include significant savings in manhours, not to mention reduced frustration to the technicians.

We urge you to take the necessary steps to make this product available.

DAVID OLEARY WG- IO, Aircraft Mechanic LBPM Production Branch C- 13 0 System Program Office

TOMMY JARRELL WG- IO, Aircraft Sheet Metal Mechanic LBPM Production Branch C-130 System Program Office

Printed on recycled paper

I am an Air Force Reserve Technician with the 439th Aircraft Wing in Chicopee Massachusetts.

I have a friend who sent me a bottle of your product. Thinking it would not work I put it in my locker to gather dust. One night while trying to take panels off an aircraft engine I was met with frustration and skinned knuckles. I tried everything I mean everything I could think of to get these screws out. I used a Johnson Bar and even attached a breaker bar to get more leverage. Nothing was working at all! I was about to go get a drill to drill the tops of the screws off and deal with whatever damage it might cause when I remembered the bottle of EZ Grip in my locker. I figured what the heck, why not, I have already wasted hours on this already. So, I got the bottle and followed the direction and OUT they came with just a regular screwdriver! I was so happy I thought I was going to bust a gut with joy. In no time at all I had the panels off and was singing praises about your product. The jet was fixed and made the mission on time all due to your product. Since then we have ordered it for the base and everyone thinks this is the best product they have ever used. We think its better than sliced bread!!!!!!!

Thank you,

Lloyd Elliott, SSgt, USAFR

Dear Sirs,

Thank you for the samples of your “ez grip” formula provided for our scrutiny.

The product was impressive when used as you suggested for removing partially rounded out Phillips type screws. One drop of ez grip in the screw slot eliminated the cam out action of the screwdriver, and made the removal of the screw an effortless operation. Removing a stubborn screw of this type in the past would require either a special impact driver, or a chiseling, drilling and time.

For your information, these samples were demonstrated and made available to other shops, and maintenance personnel with the following resulting applications:

- Removal of straight blade screws

- Removal of partially rounded out “allen” or “torx” type screws

- Removing high torque screws on aluminum engines i.e. motorcycles, lawnmower, outboard, and automotive

- A drop in a socket wrench will help remove a partially rounded hex head machine screw. This will also help a worn socket

- Removing badly corroded fasteners i.e. salt water contact, electrolysis, and plumbing

- A drop in the S.A.E. socket can aid in removing a mismatched metric screw in many size ranges, and the reverse holds true.

- A few drops on the wrench surface of a nut will eliminate slipping of an adjustable, or open end wrench

- A few drops on a slick pipe surface will assist the pipe wrench in a firm grip

In the case of damage internal threads, a drop can create an interference fit Note: This is a relatively permanent bond and should only be done when disassembly or removal is not necessary - A drop on the metal contact surface of a nut, or flange surface of a screw fastener, will, in some cases eliminate the need for a shake proof or locking washer

These are some of the interesting uses, and applications to date. The general observation is that once a person uses this product on a problem fastener, they will use it consistently as part of the removal procedure. Most of the maintenance people agree that a bottle of ez grip should be part of their tool pouch.

REF: EZ Grip Friction Drops (Aircraft Grade) Testimonials

(1) I first came across ‘EZ Grip’ approximately 10 years ago whilst working for British Airways Plc on their ‘shorthaul’ fleets and found what an amazing product it was for removing stubborn or damaged screws and preventing screw bit ‘cam out’.

Since then, ‘EZ Grip’ has been a permanent part of my toolkit where-ever I’ve worked and a much-borrowed product by fellow Aircraft Engineers; it has saved the day whilst removing panels and components on too many occasions to list.

Again, I cannot emphasize enough how much easier it is to remove fasteners with just a drop or two of ‘EZ Grip’ than without.

Well done on producing an excellent product, keep up the good work!!

Yours sincerely,

Simon Vardy

Aircraft Line Engineer

BMI

London Heathrow Airport.

Just to let you know, I was persuaded to buy this product by one of the guys who works for me. Frankly, I did not think it could do anything that it claimed. However, it is BRILLIANT stuff!

I cannot even now believe how effective it is! Even chewed up screws are easy grip and remove.

David Hockings

Cristal Air Ltd.

East Sussex

United Kingdom

Dear EZGRIP,

I own a 2400 sq. ft. cabinet shop in Southern California with quite a bit of machinery. Needless to say, something is always broke down or needs maintenance on it. While attempting to change blades on one of the planners, I managed to "round out" 4 of the gib bolts...and I mean "round out"! They are located in a 3/8 " wide channel that takes an 8mm open end wrench. I tried everything, as one could imagine, and got nowhere. Finally ( searching online) I found your product and thought I'd give it a try.To be honest, I did find it a little hard to believe what I was reading.Anyway, I received the ezgrip in about 3 days ( which is amazing in its self ) and went to work on those bolts. I have one thing to say " YOUR PRODUCT IS FRIGGING UNREAL!!!" 3 of the bolts came out like they were saying to me" What, we're not rounded out." The last one I had to use the" jiggle the wrench " a little more tricky... then it gripped ( unbelievable ) came right out!

If I had not experienced this for my self, I'm telling you, I would not believe it!

Thank You EZGRIP, I know now what to use when in a bind, and I'm sure I'll have more of them.

Sincere Thanks,

Van Cleve’s Cabinetry

San Jacinto, CA

Peter Van Cleve, Owner

Technical Data Sheet

Safety Data Sheet

Military Tests Results

©E-Z Grip Friction Drops

SMI Inc.

SCIENTIFIC MATERIAL INTERNATIONAL

12219 SW 131 Avenue Miami, Florida 33186-6401 USA

Phone (305) 971-7047 Facsimile (305) 971-7048

Attn: Larry Holt Date: 11-Apr-1995

Holt International LLC

1060 Yaple Rd. SMI/REF: 9508002-R

Kingston, OH 45644 Reissued for name change only.

Product: ©E-Z Grip Friction Drops

Dilution: As received Page 1 of 2

TOTAL IMMERSION CORROSION

per ASTM F 483

- PROCEDURE

- Weigh three of four specimens of the same alloy to the nearest 0.1 mg.

- Immerse three weighed specimens of each alloy in the solution at the prescribed temperature. Place only specimens of the same alloy in the containing vessel. Maintain at the required temperature for the prescribed exposure period. Retain the fourth specimen of each alloy for comparison purposes.

- At the end of the 24 hours remove the test specimens and proceed as follows:

- Rinse thoroughly under hot tap water, 49 to 60° C. Follow with a rinse in water conforming to ASTM D 1193, Type IV at room temperature.

- Rinse with a stream of acetone from a wash bottle and oven dry at 120° C, desiccate until cooled to ambient, weigh and record.

- Then examine for and record the following visible changes in comparison with the fourth virgin specimen of each alloy.

- Discoloration and dulling

- Etching

- Presence of accretions and relative amounts

- Pitting

- Presence of selective or localized attack

- Immerse the panels in the same test solution for a further 144 hours, then repeat 9.3.1 through 9.3.3.5.

|

Alloy |

Wgt Loss (mg per 1x2 inch panel) |

WGT LOSS mg/cm2/24hrs |

|

| AFTER 24HRS | AFTER 168HRS | ||

| AMS 4041 Clad Aluminum |

0.1 mg |

0.2 mg |

< 0.01 |

| AMS 4049 Clad Aluminum |

0.1 mg |

0.2 mg |

< 0.01 |

|

AMS 4376 Magnesium dichromate treated per MIL-M-3171 Type III |

+ 1.1 mg |

+ 1.1 mg |

+ 0.04 |

No visible corrosion or attack on any of the above alloys.

Respectfully submitted,

Patricia D. Otero, SMI Inc.

SMI Inc.

SCIENTIFIC MATERIAL INTERNATIONAL

12219 SW 131 Avenue Miami, Florida 33186-6401 USA

Phone (305) 971-7047 Facsimile (305) 971-7048

Attn: Larry Holt Date: 11-Apr-1995

Holt International LLC

1060 Yaple Rd. SMI/REF: 9503083-R

Kingston, OH 45644 Reissued for name change only.

Product: ©E-Z Grip Friction Drops

Dilution: As received

Sandwich Corrosion

per ASTM F 1110

TEST METHOD

-

- Aluminum panels having clad or anodized nonclad surfaces are sandwiched together with filter paper saturated with the test material between the panels. The sandwiched panels are cycled between warm ambient air and warm humid air for 7 days. The coupons are then inspected to determine whether corrosion more severe than that caused by a reagent water has occurred on the surfaces exposed to the test material. This test method may be used for solutions of dry granular material or for liquid materials.

-

- Relative corrosion severity rating system:

- No visible corrosion

- Very slight corrosion or discoloration (up to 5% of surface area corroded)

- Slight corrosion (5 to 15%)

- Moderate corrosion (10 to 25%)

- Extensive corrosion or pitting (25% or more)

| 2024-T3 Bare Anodized | 2024-T3 Alclad | 7075-T6 Bare Anodized | 7075-T6 Alclad | |

| As received | 1 | 1 | 1 | 1 |

| CONTROL | 1 | 1 | 1 | 1 |

Result: Conforms

Respectfully submitted,

Patricia D. Otero, SMI Inc.

SMI Inc.

SCIENTIFIC MATERIAL INTERNATIONAL

12219 SW 131 Avenue Miami, Florida 33186-6401 USA

Phone (305) 971-7047 Facsimile (305) 971-7048

Attn: Larry Holt Date: 28-Aug-1995

Holt International LLC

1060 Yaple Rd. SMI/REF: 9508002-R

Kingston, OH 45644 Reissued for name change only.

Product: ©E-Z Grip FRICTION DROPS

Dilution: As received

Hydrogen Embrittlement

per ASTM F 519, Type 1C

Test Procedure:

-

-

- TYPE 1C SPECIMENS

- Load a minimum of three specimens to 45% of the bend strength.

- Put the test solution into a clean plastic container, place the stressed specimens in the test solution, and record the time to failure if less than 150 hours. The test may be discontinued after 150 hours.

- TYPE 1C SPECIMENS

-

INTERPRETATION OF RESULTS

-

- Failure of all specimen types occurs by readily visible detectable fracture processes.

As received: No failures within 150 hours. (Product layers upon standing)

Result: Conforms

Respectfully submitted,

Patricia D. Otero, SMI Inc

SMI Inc.

SCIENTIFIC MATERIAL INTERNATIONAL

12219 SW 131 Avenue Miami, Florida 33186-6401 USA

Phone (305) 971-7047 Facsimile (305) 971-7048

Attn: Larry Holt Date: 11-Apr-1995

Holt International LLC

1060 Yaple Rd. SMI/REF: 9503083-R

Kingston, OH 45644 Reissued for name change only.

Product: ©E-Z Grip Friction Drops

Dilution: As received

ASTM F 1111-88

CORROSION OF LOW-EMBRITTLING CADMIUM PLATE

BY AIRCRAFT MAINTENANCE CHEMICALS

SCOPE

This test method is intended as a means of determining the corrosive effects of aircraft maintenance chemicals on low-embrittling cadmium plating used on aircraft high-strength steel, under conditions of total immersion by quantitative measurements of weight change.

PROCEDURE

Dry the precleaned specimens at 110° C for 1 hour, allow to cool to room temperature in a deslccator, then weigh to the nearest 0.1 mg.

Transfer the specimens to the vessel containing the preheated maintenance chemical solution. Seal the test vessel to prevent loss of vapor. Maintain at the required temperature and expose for a period of 24 hours.

Remove the specimens at the end of the exposure period and proceed as follows:

- Hold the specimen in forceps and rinse thoroughly in a 1 liter beaker into which tap water is flowing rapidly.

- Rinse thoroughly in water at room temperature.

- Rinse with a stream of acetone from a wash bottle. Shake free from acetone and dry.

- Place the specimens in an oven at 110 +/- 2° C for 1 hour and allow to cool to room temperature in a desiccator.

- Reweigh the specimens to the nearest 0.1 mg and record.

Average weight loss per 1" x 2" panel:

0.5 mg/cm2/24hrs.

Respectfully submitted,

Patricia D. Otero, SMI Inc.

SMI Inc.

SCIENTIFIC MATERIAL INTERNATIONAL

12219 SW 131 Avenue Miami, Florida 33186-6401 USA

Phone (305) 971-7047 Facsimile (305) 971-7048

Attn: Larry Holt Date: 02-Oct-1995

Holt International LLC

1060 Yaple Rd. SMI/REF: 9509036-R

Kingston, OH 45644 Reissued for name change only.

Product:E-Z Grip (Marine Formula) (rec'd 13-Sep-1995)

Dilution: As received (well shaken before use)

MIL-R-81294D

Paragraph 4.6.4.3.1

Notched C-Ring

-

-

-

-

- Notched C-Ring

-

-

-

-

-

-

-

-

- Procedure. The ring shall be stressed to 65 percent of the predetermined average breaking strength by tightening the nut until the diameter of the ring, measured across the bolt, is reduced to the calculated value. (In most cases the diameter will be reduced by 0.22 cm (0.087 inch). Any steel bolt of suitable size may be used for the stressing. If equipment is available, this may be done more accurately with a strain indicator and a loading bolt containing a strain gauge. The stressed ring shall be immersed for 60 seconds in the paint remover sample with the notched side down to a point where the ring is covered approximately one inch on either side of the notch. The rings shall be removed and allowed to hang notched side down in air for 100+/- hours. No rinse of any kind shall be used after dipping. Suitable hangers may be made of plastic or rubber coated wire. The rings shall not break or crack during the 100 hour test period.

-

-

-

-

Result: Conforms

Respectfully submitted,

Patricia D. Otero, SMI Inc.

Note: This procedure was selected as it most closely resembled the requirements outlined by Jim Muller.

E-Z Grip Marine Grade

SMI Inc.

SCIENTIFIC MATERIAL INTERNATIONAL

12219 SW 131 Avenue Miami, Florida 33186-6401 USA

Phone (305) 971-7047 Facsimile (305) 971-7048

Attn: Larry Holt Date: 28-Aug-1995

Holt International LLC

1060 Yaple Rd. SMI/REF: 9508002-R

Kingston, OH 45644 Reissued for name change only.

Product: E-Z Grip (Marine Formula) (rec'd 16-Aug-1995)

Dilution: As received (shaken well before testing) Page 1 of 2

TOTAL IMMERSION CORROSION

per ASTM F 483

- PROCEDURE

- Weigh three of four specimens of the same alloy to the nearest 0.1 mg.

- Immerse three weighed specimens of each alloy in the solution at the prescribed temperature. Place only specimens of the same alloy in the containing vessel. Maintain at the required temperature for the prescribed exposure period. Retain the fourth specimen of each alloy for comparison purposes.

- At the end of the 24 hours remove the test specimens and proceed as follows:

- Rinse thoroughly under hot tap water, 49 to 60° C. Follow with a rinse in water conforming to ASTM D 1193, Type IV at room temperature.

- Rinse with a stream of acetone from a wash bottle and oven dry at 120° C, desiccate until cooled to ambient, weigh and record.

- Then examine for and record the following visible changes in comparison with the fourth virgin specimen of each alloy.

- Discoloration and dulling

- Etching

- Presence of accretions and relative amounts

- Pitting

- Presence of selective or localized attack

- Immerse the panels in the same test solution for a further 144 hours, then repeat 9.3.1 through 9.3.3.5.

No visible corrosion or attack on any of the above alloys.

Respectfully submitted,

Patricia D. Otero, SMI Inc.

SMI Inc.

SCIENTIFIC MATERIAL INTERNATIONAL

12219 SW 131 Avenue Miami, Florida 33186-6401 USA

Phone (305) 971-7047 Facsimile (305) 971-7048

Attn: Larry Holt Date: 28-Aug-1995

Holt International LLC

1060 Yaple Rd. SMI/REF: 9508002-R

Kingston, OH 45644 Reissued for name change only.

Product: E-Z Grip (Marine Formula) (rec'd 16-Aug-1995)

Dilution: As received (shaken well before testing)

Sandwich Corrosion

per ASTM F 1110

TEST METHOD

-

- Aluminum panels having clad or anodized nonclad surfaces are sandwiched together with filter paper saturated with the test material between the panels. The sandwiched panels are cycled between warm ambient air and warm humid air for 7 days. The coupons are then inspected to determine whether corrosion more severe than that caused by a reagent water has occurred on the surfaces exposed to the test material. This test method may be used for solutions of dry granular material or for liquid materials.

-

- Relative corrosion severity rating system:

- No visible corrosion

- Very slight corrosion or discoloration (up to 5% of surface area corroded)

- Slight corrosion (5 to 15%)

- Moderate corrosion (10 to 25%)

- Extensive corrosion or pitting (25% or more)

|

2024-T3 Bare Anodized |

2024-T3 Alclad |

7075-T6 Bare Anodized |

7075-T6 Alclad |

|

| As received |

1 |

1 |

1 |

1 |

| CONTROL |

1 |

1 |

1 |

1 |

Result: Conforms

Respectfully submitted,

Patricia D. Otero, SMI Inc.

SMI Inc.

SCIENTIFIC MATERIAL INTERNATIONAL

12219 SW 131 Avenue Miami, Florida 33186-6401 USA

Phone (305) 971-7047 Facsimile (305) 971-7048

Attn: Larry Holt Date: 11-Apr-1995

Holt International LLC

1060 Yaple Rd. SMI/REF: 9503083-R

Kingston, OH 45644 Reissued for name change only.

Product:©E-Z Grip FRICTION DROPS

Dilution: As received

Hydrogen Embrittlement

per ASTM F 519, Type 1C

Test Procedure:

-

-

- TYPE 1C SPECIMENS

- Load a minimum of three specimens to 45% of the bend strength.

- Put the test solution into a clean plastic container, place the stressed specimens in the test solution, and record the time to failure if less than 150 hours. The test may be discontinued after 150 hours.

- TYPE 1C SPECIMENS

-

INTERPRETATION OF RESULTS

-

- Failure of all specimen types occurs by readily visible detectable fracture processes.

As received: No failures within 150 hours. (Product layers upon standing)

Result: Conforms

Respectfully submitted,

Patricia D. Otero, SMI Inc.

SMI Inc.

SCIENTIFIC MATERIAL INTERNATIONAL

12219 SW 131 Avenue Miami, Florida 33186-6401 USA

Phone (305) 971-7047 Facsimile (305) 971-7048

Attn: Larry Holt Date: 28-Aug-1995

Holt International LLC

1060 Yaple Rd. SMI/REF: 9508002-R

Kingston, OH 45644 Reissued for name change only.

Product: E-Z Grip (Marine Formula) (rec'd 16-Aug-1995)

Dilution: As received

ASTM F 1111-88

CORROSION OF LOW-EMBRITTLING CADMIUM PLATE

BY AIRCRAFT MAINTENANCE CHEMICALS

SCOPE

This test method is intended as a means of determining the corrosive effects of aircraft maintenance chemicals on low-embrittling cadmium plating used on aircraft high-strength steel, under conditions of total immersion by quantitative measurements of weight change.

PROCEDURE

Dry the precleaned specimens at 110° C for 1 hour, allow to cool to room temperature in a deslccator, then weigh to the nearest 0.1 mg.

Transfer the specimens to the vessel containing the preheated maintenance chemical solution. Seal the test vessel to prevent loss of vapor. Maintain at the required temperature and expose for a period of 24 hours.

Remove the specimens at the end of the exposure period and proceed as follows:

- Hold the specimen in forceps and rinse thoroughly in a 1 liter beaker into which tap water is flowing rapidly.

- Rinse thoroughly in water at room temperature.

- Rinse with a stream of acetone from a wash bottle. Shake free from acetone and dry.

- Place the specimens in an oven at 110 +/- 2° C for 1 hour and allow to cool to room temperature in a desiccator.

- Reweigh the specimens to the nearest 0.1 mg and record.

Average weight loss per 1" x 2" panel: +0.12 mg/cm2/24hrs

Product layers upon standing.

Respectfully submitted,

Patricia D. Otero, SMI Inc.

SMI Inc.

SCIENTIFIC MATERIAL INTERNATIONAL

12219 SW 131 Avenue Miami, Florida 33186-6401 USA

Phone (305) 971-7047 Facsimile (305) 971-7048

Attn: Larry Holt Date: 02-Oct-1995

Holt International LLC

1060 Yaple Rd. SMI/REF: 9509036-R

Kingston, OH 45644 Reissued for name change only.

Product: E-Z Grip (Marine Formula) (rec'd 13-Sep-1995)

Dilution: As received (well shaken before use)

MIL-R-81294D

Paragraph 4.6.4.3.1

Notched C-Ring

-

-

-

-

- Notched C-Ring

-

-

-

-

-

-

-

-

- Procedure. The ring shall be stressed to 65 percent of the predetermined average breaking strength by tightening the nut until the diameter of the ring, measured across the bolt, is reduced to the calculated value. (In most cases the diameter will be reduced by 0.22 cm (0.087 inch)). Any steel bolt of suitable size may be used for the stressing. If equipment is available, this may be done more accurately with a strain indicator and a loading bolt containing a strain gauge. The stressed ring shall be immersed for 60 seconds in the paint remover sample with the notched side down to a point where the ring is covered approximately one inch on either side of the notch. The rings shall be removed and allowed to hang notched side down in air for 100+/- hours. No rinse of any kind shall be used after dipping. Suitable hangers may be made of plastic or rubber coated wire. The rings shall not break or crack during the 100 hour test period.

-

-

-

-

Result: Conforms

Respectfully sumbitted,

Patricia D. Otero, SMI Inc.

Note: This procedure was selected as it most closely resembled the requirements outlined by Jim Muller.